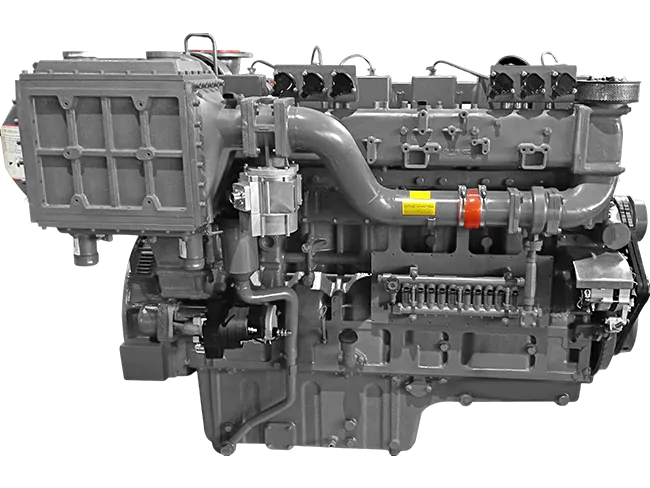

| Name |

Technical specifications |

| Category |

Marine propulsion engine |

Marine propulsion engine |

Marine propulsion engine |

Marine propulsion engine |

Marine G-drive auxiliary engine |

| Model |

YC6TD540NL-C20 |

YC6TD520NL-C20 |

YC6TD500NL-C20 |

YC6TD545NL-C20 |

YC6TD480NL-C20 |

YC6TD450NL-C20 |

YC6TD410NL-C20 |

YC6TD335NL-C20 |

YC6TD295NL-C20 |

YC6TD275NL-C20 |

YC6TD195NL-C20 |

YC6TD380NL-C20 |

YC6TD490NL-C25 |

YC6TD410NL-C25 |

| Type |

Vertical, in-line, water-cooled, four-stroke |

Vertical, in-line, water-cooled, four-stroke |

Vertical, in-line, water-cooled, four-stroke |

Vertical, in-line, water-cooled, four-stroke |

Vertical, in-line, water-cooled, four-stroke |

| Induction system |

Turbocharged & intercooled |

Turbocharged & intercooled |

Turbocharged & intercooled |

Turbocharged & intercooled |

Turbocharged & intercooled |

| 气缸数 |

6 |

6 |

6 |

6 |

6 |

| Bore mm |

152 |

152 |

152 |

152 |

152 |

| Stroke mm |

180 |

180 |

180 |

180 |

180 |

| Displacement L |

19.6 |

19.6 |

19.6 |

19.6 |

19.6 |

| Rated power kW |

396 |

382 |

368 |

400 |

352 |

330 |

300 |

246 |

217 |

202 |

143 |

279 |

360 |

300 |

| Rated speed r/min |

1800 |

1500 |

1500 |

1500 |

1200 |

1500 |

| Overload power kW |

435.6 |

420.2 |

404.8 |

440 |

387.2 |

363 |

330 |

270.6 |

238.7 |

222.2 |

157.3 |

306.9 |

396 |

330 |

| Overload speed r/min |

1858 |

1548 |

1548 |

1548 |

1239 |

1500 |

| Minimum steady-state speed with load r/min |

≤810 |

≤675 |

≤675 |

≤675 |

≤540 |

- |

| Average piston speed m/s |

10.8 |

9 |

9 |

9 |

7.2 |

9 |

| Mean effective pressure MPa |

1.347 |

1.299 |

1.252 |

1.633 |

1.437 |

1.347 |

1.224 |

1.004 |

0.886 |

0.824 |

0.584 |

1.423 |

1.592 |

1.327 |

| Firing order |

1—5—3—6—2—4 |

1—5—3—6—2—4 |

1—5—3—6—2—4 |

1—5—3—6—2—4 |

1—5—3—6—2—4 |

| Rotation |

Anticlockwise (facing the power output end) |

Anticlockwise (facing the power output end) |

Anticlockwise (facing the power output end) |

Anticlockwise (facing the power output end) |

Anticlockwise (facing the power output end) |

| Starting mode |

Electric start |

Electric start |

Electric start |

Electric start |

Electric start |

| Fuel |

LNG |

LNG |

LNG |

LNG |

LNG |

| Oil capacity L |

52 |

52 |

52 |

52 |

52 |

| Steady-state speed regulation % |

≤10 |

≤10 |

≤10 |

≤10 |

≤5 |

| Instantaneous speed regulation % |

≤15 |

≤15 |

≤15 |

≤15 |

≤10 |

| Emission |

China II marine engines |

China II marine engines |

China II marine engines |

China II marine engines |

China II marine engines |

| Diemension(Length × width × height) mm |

1981×1186×1638(Diemension may vary with configuration.) |

1981×1186×1638(Diemension may vary with configuration.) |

1981×1186×1638(Diemension may vary with configuration.) |

1981×1186×1638(Diemension may vary with configuration.) |

1981×1186×1638(Diemension may vary with configuration.) |

| Dry weight kg |

2400 |

2400 |

2400 |

2400 |

2400 |