February 2025, the Ministry of Industry and Information Technology of China announced the list of the first batch of “Exemplary Smart Factory” projects. Among them, Yuchai’s end-to-end digitally-driven smart factory for engine production successfully made the list.

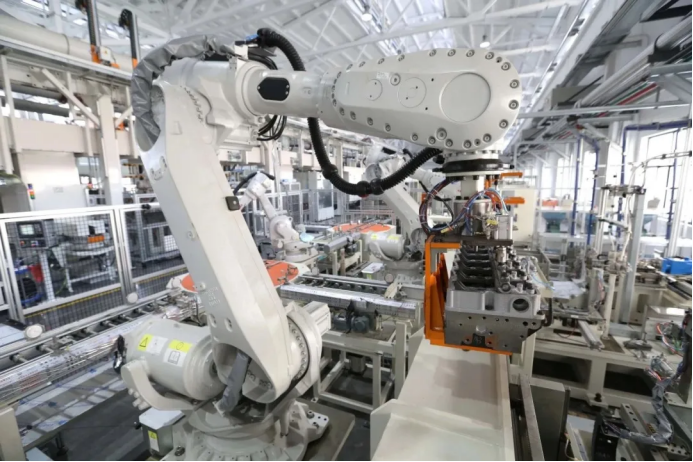

Since 2018, Yuchai has invested nearly 3 billion yuan to simultaneously upgrade its new-generation National VI production lines with intelligent technologies. The factory has fully integrated 5G technology, established a digital monitoring system for its management hub, and achieved full automation in engine production. Since its operation, the factory has significantly improved the production rate of Yuchai engines. A single engine can now be qualified and rolled off the production line in just 12 hours, reducing the production cycle by 80%.

Compared to traditional workshops that relied heavily on manual labor for precision machining, Yuchai’s National VI production line has realized fully intelligent engine production through digital transformation. The machining precision of cylinder bores has reached 1 micron, far exceeding the domestic average. Additionally, workers’ labor intensity has decreased by over 90%, while manufacturing efficiency has increased by more than 50%.

Supported by advanced manufacturing capabilities, Yuchai has recently launched a series of innovative products, including the world’s first hybrid electric continuously variable transmission powertrain and China’s first hydrogen-fueled engine for commercial vehicles. These achievements have led the development of China’s power equipment industry toward high-end, intelligent, and green solutions. Today, Yuchai’s products cover nearly 100 market segments, including trucks, buses, construction machinery, ships, and power generation equipment, earning it the reputation of a “power supermarket.”